Many businesses, maybe yours as well, are always trying to find a way to grow and to succeed. However, to achieve it, many organisations implement initiatives to achieve that growth and to achieve greater profitability, now and in the future. But despite these initiatives, the same organisations fail not only to improve their business, but by implementing these initiatives experience greater costs and find themselves in worse positions than they were before.

Why is this? Because they fail to find the key issue that is holding their business back, the constraint, that upon being improved upon improves the whole business. Any improvements on any part of the business that is not the constraint, in most times actually make the business worse. This is a key insight provided by a lesser known management philosophy called The Theory of Constraints.

If you are in the world of Continuous Improvement you may have come across the term, Theory of Constraints, but in this article I’ll explain what it is and how it can help your business.

The Theory of Constraints (TOC) is a management philosophy that helps organizations seeking to enhance efficiency, reduce waste, and achieve operational excellence. Described in various business novels written by Dr. Eliyahu M. Goldratt and expanded by proponents, the Theory of Constraints is a philosophy that identifies, manages, and overcomes bottlenecks and constraints within an organization.

This article will talk about two key concepts in the Theory of Constraints, The Five Focusing Steps, and The Logical Thinking Processes. I’ll even tell you how I used it in an operation I managed to show how it can be used.

After reading this article, I highly suggest you read the business novels about TOC. They are captivating reads. Be mindful, however, that sometimes you will go through a chapter every now and then and not understand the point of the chapter. They are business novels after all, and sometimes certain plot points don’t make sense to the reader until much later in the book.

The first book, The Goal, is a great starter that explains one of the greatest tools in TOC, The Five Focusing Steps. You will be taken on a journey as if you are in the shoes of a plant manager struggling to figure out how to improve his operation (plant) and bring it back to profitability and improve stakeholder outcomes.

The second book, It’s Not Luck, looks into how the Theory of Constraints can be used to form business strategy and improve marketing and sales. Many concepts are explained, in particular, The Logical Thinking Processes.

I, personally, have used the concepts behind the Theory of Constraints to improve my own operations in the various organisations I have worked at and been a manager. While those organisations did not have a continuous improvement initiative in place and the words Theory of Constraints weren’t even a thought to anyone else (that I know of), I was still able to apply these concepts to my operation and so can you!

On top of that, many of the tools in Lean and Six Sigma work perfectly with the Theory of Constraints. They do complement each other well, but be aware that there are a few key differences.

Alternate Names: Constraint Management, Constraint and Buffer Management

While commonly known as the Theory of Constraints, this methodology is sometimes called an alternate name, Constraint Management. My personal way to describe it is “Constraint and Buffer Management” as placing the right buffers in the right places can lead to large improvements in throughput of the organisations. These alternate titles emphasize the core concept of identifying and managing constraints within an organization.

Uses of The Theory Of Constraints

If there is one defining factor that separates The Theory of Constraints from other management philosophies is that it can be applied to every industry and to every organisation. Unlike Lean or Six Sigma which is catered primarily to manufacturing, what separates TOC is that it is a way of thinking. It is a set of mental models of how to think about how organisations work as a system.

In systems, many parts work together towards achieving a goal. No change to one part of the system acts independently of the system it operates in. You make a change in one area, it impacts other parts of the system, in many ways that some people don’t expect.

The Theory of Constraints thinks in terms of systems. Therefore, it focuses on what part of the system is restricting it from achieving its goal, but also takes into consideration what impacts a change to one part of the system makes to the whole organisation.

Hospitals for example is a different system than a restaurant which is different again from a manufacturing company.

The 5 Focusing Steps:

Identify the Constraint

The first step is to pinpoint the constraint, often referred to as the “bottleneck.” This is the point in the system that limits overall throughput (sales) of the organisation.

Constraints can be classed as two types, internal or external.

Internal constraints exist when there is greater demand for an organisations product or service than the organisation is capable of servicing. By identifying the key process or division or department that acts as the constraint, key continuous initiatives can be implemented to improve on that constraint. For example, an internal bottleneck could be a production machine with limited capacity or your quality control department that slows down the release of products to the customer.

Relevant Key Performance Indicators (KPIs) for organisations with internal bottlenecks may include lead times, and Delivery-In-Full-On-Time (DIFOT).

External constraints, for example, can be situations where an organisation is capable of servicing current levels of customer demand. Therefore, in order to improve profitability, now and in the future, The Theory of Constraints, would look at how customer demand can be increased which may include formulating better product offerings, improving your marketing to generate more leads and creating more effective strategies to convert leads into more sales etc.

Tools provided by the Theory of Constraints to identify the constraint can be the Current Reality Tree (explained later in this article).

Exploit the Constraint

Once the constraint is identified, the it should be maximally exploited. This involves ensuring that the bottleneck is fully utilized, with no unexpected downtime.

“Exploiting” in this sense, means making 1) improvements to the constraints and 2) ensuring that the constraint (for the sake of this example, let’s say a machine) is working as close to 100% of the time.

While the business novels provide ideas of improvements, they were largely for the specific operational issues in the books. Your business may be different (most likely so) and therefore those solutions won’t be relevant for you.

However, other methodologies such as Lean and Six Sigma provide many tools that work amazingly well to “exploit” internal constraints in the business. Other skills such as data analysis can also be useful. For external constraints, marketing and sales skills can be highly beneficial.

In my own case, I had a machine which was the constraint in my operation. Lean, Six Sigma and my skills in data analysis helped me identify issues within the constraint and helped me come up with solutions to resolve it.

To explain, I was a manager in the freight forwarding industry and in my department was a machine that sorted parcels by location. It scanned barcodes on parcels and with the information provided through stock files, the machine could determine which chute the parcel should go down, where a worker would then place the parcel in the relevant container.

Tools provided by Lean called Overall Equipment Effectiveness (OEE) along with the Six Big Losses and Process Failure Modes and Effect Analysis (Process FMEA) from Six Sigma allowed me to identify weak points between the machine uptime, machine throughput and output quality.

I then implemented solutions to each of the identified issues and boom, throughput of the machine went up 30% and output quality went up to 99%.

It is at this stage, that Lean and Six Sigma can really shine through improving process stability, creating flow and implementing pull systems. I’ll write an article later about what that all means.

Another point to make is that implementing the solutions that will improve the constraint can be challenging. TOC provides tools such as the Future Reality Tree (FRT), also called the Solution Tree, and the Prerequisite Tree (or Deployment Tree) to assist people in creating the solution and implement it.

Subordinate Everything Else

The third step involves aligning all other activities and processes to support and match pace with the constraint. This ensures that non-bottleneck activities do not overwhelm the constraint.

To explain further, any processes before the constraint and after the constraint needs to have their process outputs in line with the throughput of the constraint. If the machine, for example, could only process 2500 parcels and hour, processes before it should not be processing more than 2500 parcels an hour. The same goes for processes after the constraint. In essence, the constraint sets the drumbeat (rhythm) of the operation.

For those who have learnt Lean, this may sound similar to Takt Time. However, in the case where there is an internal constraint, rather than measure the rhythm of the operation to customer demand, it is measured to the pace set by the constraint. Where an organisation is experiencing an external constraint, then measuring against Takt Time may be appropriate. But unlike Lean, the Theory of Constraints would look to increase customer demand as that is then the constraint preventing an organisation from achieving its goal of greater profitability now and in the future.

In the world of The Theory of Constraints, we’d look to implement a tool called Drum, Buffer, Rope (or DBR for short) at the constraint. Don’t worry, there will be no actual drums and ropes involved. It is the name of the concept where the drum is the pace of the constraint, the buffer is a minimal amount of work in progress material on hand to make sure the constraint is constantly operating and never starved of material and the rope is the signaling device telling the upstream processes to release and process more goods.

The “rope” goes from the buffer so as more work in progress material goes into the constraint (say a machine) the rope signals to the processes upstream to release material to replenish the buffer which has been used up.

Why is there a buffer in front of the constraints? Aren’t we suppose to have no work in progress material?

Two very good questions. The buffer exists to make sure there is always material for the constraint due to the variability of processes upstream to the constraint. It is natural to expect that upstream processes aren’t always going to work 100% of the time and sometimes fail to provide enough material at the right time for the constraint. Things break down and unexpected events occur. We call these “Murphy” after Murphy’s Law. Because of this reality, if things upstream do breakdown, which by the way should not be happening often, then the constraint can continue to produce output while the upstream processes get fixed and then catch up to replenish the buffer.

If the buffer was not there with no work in progress material, then the second something goes wrong upstream, the output of the entire system stops because there is nothing for the constraint to produce.

Elevate the Constraint

Up to now, we have talked about how to identify the constraint, exploit it (make improvements and ensure it operates close to 100% of the time) and then how to subordinate every other part of the business. Now its time to talk about the 4th step.

But before doing so, I want to note that in many cases, at step 2, exploiting the constraint is enough to improve it to such a degree that it no longer is the constraint. In the example I gave above with my own experience, the process changes and improvements to the machine I implemented were enough for it to no longer be the constraint. In these situations, we’d say the constraint has moved. But I’ll explain that further below.

Let’s say for example, that at step 2 you have come up with all possible (we know we can never say this with certainty) solutions and quick fixes to improve (exploit) the constraint and from there you have subordinated other parts of the business, now you must “elevate the constraint”.

What this means is that you have to invest in more capacity either in more machinery, workers, buildings etc. until the constraint is no longer the constraint. This of course is a last resort. Taking on more machinery, workers and buildings is not cheap and before doing so we need to ensure we have come up with as many ideas to improve the constraint by increasing efficiency, reliability and effectiveness before investing in more capacity.

In my example, from my own experiences, we improved all of our processes to the point that none of them were constraints, i.e., we shifted the constraint externally. We become so operationally excellent that now our key issue was that we had, during many times of the week, nothing to do.

Eventually, however, our sales team bought in more clients and our volumes to be processed skyrocketed.

I can never get a break, can I?

As we already exploited every efficiency we can come up with, we knew that in order to satisfy the extra demand, we had to take on more workers and more machines, in our case, was more ride-on pallet jacks.

Though this increase capacity bought on by more staff and more machinery, we were then able to satisfy the increasing customer demand.

This is an example of both, how increasing capacity is sometimes the only solution you may have left to improve on a constraint and second, how constraints can move when one has been exploited and elevated.

Repeat the Process

Continuously assess the system to identify new constraints and repeat the focusing steps to achieve ongoing improvement.

The Logical Thinking Processes

The Logical Thinking Processes (LTP) are designed to to help people break down problems into smaller, easier to understand parts and improve decision-making within organizations. Another benefit is that by putting thoughts to paper, it can help improve communication between team members and help build collaboration to improve the organisation.

In many ways, by logically going through a problem people can identify, with a higher likelihood of success, what the problem is that they are facing, what needs to change, what to change it to and how to change it. Often organisations want people who can solve problems and the Logical Thinking Processes allow you to do just that.

Each of the Logical Thinking Processes are explained below:

Current Reality Tree (CRT) (also called the Problem Tree)

The Current Reality Tree is a tool to visually represent the current problem or situation. By identifying cause-and-effect relationships, it helps in understanding the root causes of an issue. This tool is specifically designed to identify the root causes, not create a solution for it. To put it in another way, it identifies what needs to change.

To simplify this, a business often has multiple issues to deal with. What most fail to realize is that often many of the issues are linked i.e., one causes the other. It is important to find out what problems are simply symptoms of another problem or issue, which may be the root cause. By identifying the root cause and creating an effective solution to it, you may be able to resolve multiple problems to the organisation.

That is the power of the Current Reality Tree. Recognizing the constraint that impacts the whole system is what the Current Reality Tree is designed to do.

To relate this to something you might be aware of, let’s say you have the flu. You might experience headaches, sore muscles, runny nose, sneezing, coughing etc. You get the idea. These are symptoms and while they are problematic, they aren’t the root cause. It is a viral infection. A virus is what is causing all of these problems.

In many organisations, however, they focus on resolving the symptoms, not the root cause. So what happens then is that the issue continues to return.

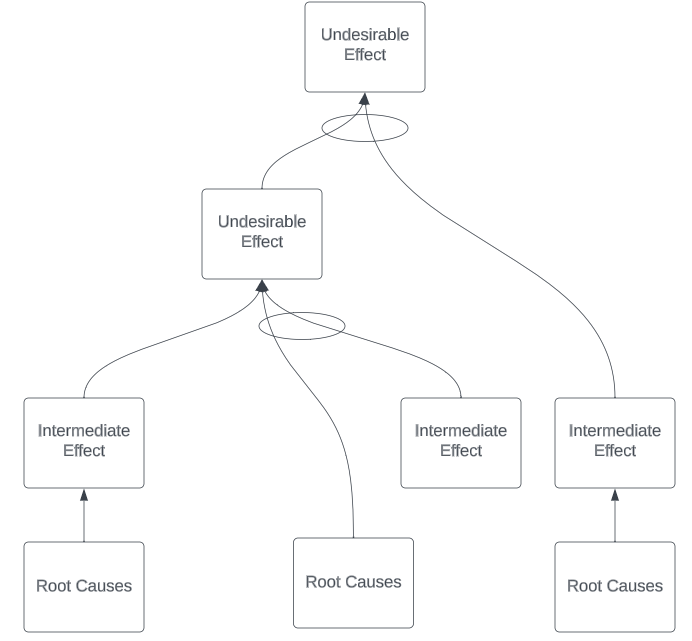

The Current Reality Tree can look like below:

There are three core parts to a current reality tree: Undesirable Effects (UDEs), Intermediate Effects and Root Causes.

Undesirable Effects (UDEs) are the negative outcomes or consequences within the Current Reality Tree (CRT) that highlight the undesirable or problematic aspects of a situation. These effects are the symptoms or manifestations of the core problems (root causes) identified within the CRT. They often serve as starting points for the analysis, allowing teams to trace backward from these undesirable effects to identify their underlying causes and interconnected factors.

Intermediate Effects: If Undesirable Effects represent the visible symptoms or negative outcomes, Intermediate Effects help to further illustrate the chain of cause and effect within the problem-solving process. They contribute to understanding the sequence of events that show how one thing causes the other. They act to help guide people to understanding the thought process as often it can take a few intermediate steps to link a Root Cause to an Undesirable Effect. In the example I gave below, I linked the lack of profitability (the Undesirable Effect) to a few root causes but there were several intermediate effects to explain the logic.

Root Causes within the context of the Current Reality Tree (CRT) represent the fundamental origins or core factors that lead to Undesirable Effects.

The circles you will notice on certain lines indicate that there are two (or sometimes more) effects that contribute to the factor above it.

How the CRT works is that there is a clear if… then… logic. There are situations where you can have an Undesirable Effect leading to another Undesirable Effect or an 2 intermediate effect with another intermediate effect leading to an undesirable effect etc. Linked to some of these are the root causes shown at the bottom of the CRT.

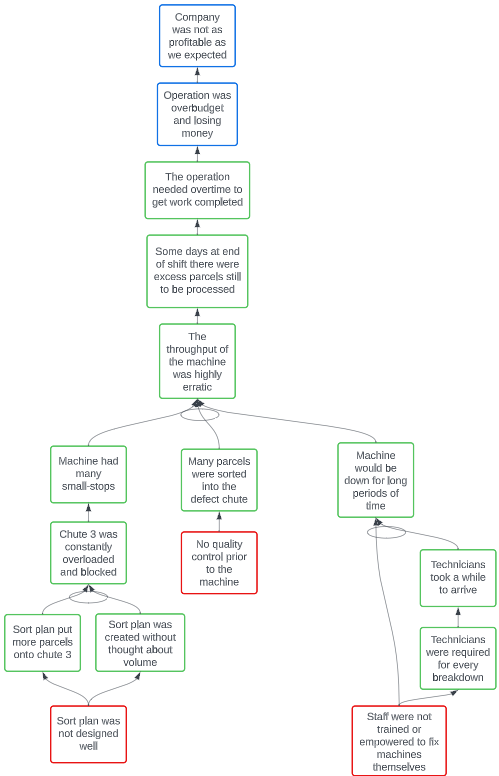

Example:

The way you read the Current Reality Tree is that you start from the top and make your way down each of the branches one at a time. By starting with the Undesirable Effects, you move your way to identifying through a logical sequence till you get to the root cause. When explaining the tree to others you can say “we experience… because…”. For example, “we experience [that] the operation needed overtime to get work completed because some days at end of shift there were excess parcels still to be processed”.

In this example above which came from my own experience managing an operation you can see the Current Reality Tree I had created. It was not perfect but it helped identify the Undesirable Effects (UDEs)(in Blue), the Intermediate Effects (in Green) and the Root Causes (in Red). From there we were able to move onto the Future Reality Tree where we figured out what initiatives to implement to address the root causes i.e., fixing the sort plan, training and empowering staff to fix the machine and implementing quality control before the machine.

I’ll note that the CRT I have shown above is actually only part of a much bigger tree with 2 other branches but I wouldn’t have enough space to include it all without you needing to squint your eyes.

In the future, I’ll write a more detailed article specifically about the Current Reality Tree, how to create it and how to implement it.

Future Reality Tree (FRT) (Also called Solution Tree)

Once the current problems and root causes are understood from the Current Reality Tree (CRT), the Future Reality (FRT) is used to map out a desired future state where the issues have been addressed and the Undesirable Effects no longer exist. It constructs a logical path from the present situation to a desired future state, considering cause-and-effect relationships.

In the Future Reality Tree, there are “Injections” which are the initiatives and solutions that need to have been implemented in order to achieve the desired future state. Be aware that the Future Reality Tree does not detail how the injections will actually work or how they were created in the first place. It simply outlines how the injections are expected to create the desired future state. The FRT is used often to help get buy-in from more senior people in the business who often have the authority to decide on which initiatives to implement. By showing the Future Reality Tree, it helps them visually understand how implementing the injections should create the desired future state.

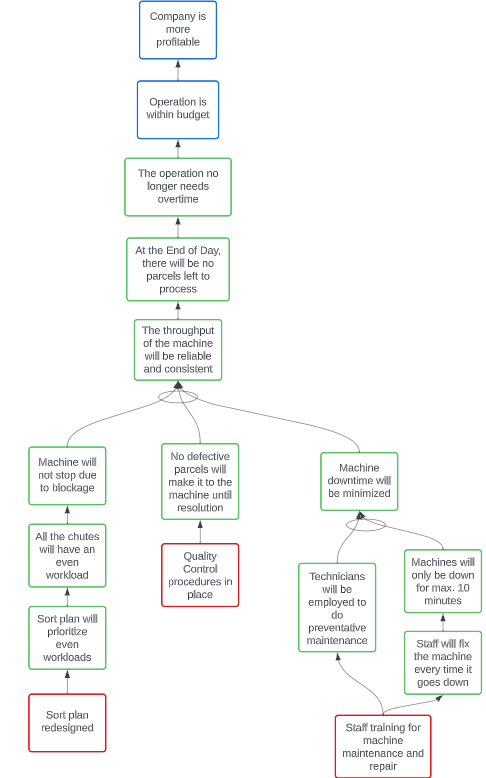

Example:

As you can see in the example I have provided, it looks quite similar to the Current Reality Tree shown above but with a few key differences. The Blue boxes are now Desirable Effects, the Green Boxes are still Intermediate effects but will be the desired effects and the red boxes are the injections.

Note that the injections are the initiatives we hope to initiate and you can use the logic to see how it will lead to our desired future state which is that the company is more profitable. However, the Future Reality Tree as mentioned above is not used to determine how we will create the injection. That is the job of the pre-requisite tree.

Prerequisite Tree (PRT) (also called a Deployment Tree)

The Prerequisite Tree identifies what steps and actions are required to implement the solutions (injections) identified in the Future Reality Tree.

Think of it like creating a project roadmap to determine what needs to be done, when it should be done, by whom, what obstacles we may face and therefore what we should do to address those obstacles.

The construction of the Prerequisite Tree involves a logical approach. It starts by identifying the objectives from the Future Reality Tree and then proceeds to break it down into further more detailed actions that must be met or accomplished to fulfill those objectives. This process involves thorough analysis and deliberation among stakeholders to ensure that all essential prerequisites are recognized and structured in a logical and feasible sequence.

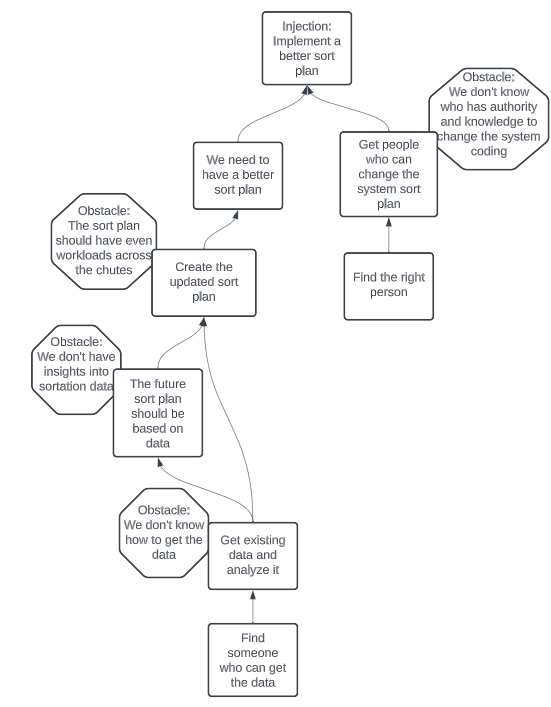

Example:

As you can see, in order to implement the injection of a better sort plan for the machine for which I was in charge of there were quite a few things that needed to be accomplished. As you go lower down the tree from the injection there are further breakdowns. At each point there may be obstacles as shown in octagons. These obstacles can then help people determine what is then necessary to overcome those obstacles.

The lower an item is in the Prerequisite Tree, the earlier in the deployment the action needs to take place. In the example above, the first steps were to find people who can get the current data and analyze it and find someone who could change the system coding. From there we could then take actions further up the tree until we get to the stage where we can implement the injection.

Evaporating Cloud (EC) (also called Conflict Resolution)

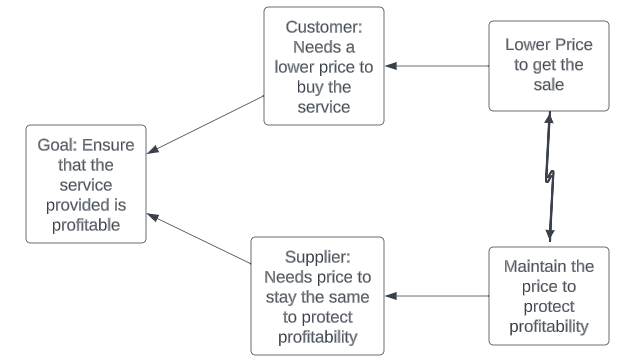

Often in trying to create a solution to problems, you may encounter situations where there are two conflicting issues. Solutions that may seem obvious, in this case, would however benefit one party or fix one issue but make worse the other. The Evaporating Cloud technique helps in visualizing opposing viewpoints or goals. After visualizing the conflict, people can work together to come up with ideas with the aim to find common ground between conflicting parties and create win-win solutions that benefit both parties.

This technique derives its name from the analogy of a cloud, where the conflicting positions or beliefs are represented on either side, and the aim is to dissipate the cloud of conflict.

The process of constructing an Evaporating Cloud involves stating what the goal is that the organisation wishes to achieve and then expresses the needs and actions/wants of the two parties. I’ve given an example below.

This is a situation faced all to often by people involved in sales departments or entrepreneurs trying to build up their business. Customers want lower prices and suppliers want to keep prices high to protect profitability, therefore there is a situation where both conditions cannot be satisfied.

As you can see, the Evaporating Cloud simply visualizes the problem. In team environments this helps keep conversation on track to helping come up with solutions.

So what can be done here? As the supplier, we can come up with a few solutions that can be mutually beneficial. First we need to understand what issues the customer is facing that makes them pushback and want to lower the price.

Are they:

- facing cash flow issues and actually cannot afford the price

- just trying to negotiate with you and see what kind of person you are

- not recognizing the value you are providing them

After listing the potential reasons, you can for the first pushback, change the pricing structure so instead of one large payment up-front, you split the payments over time. You can also change the way it is offered from a sale to a subscription such as rent where the supplier retains ownership and lowers the price paid by the customer in the short term . This can work for heavy or expensive equipment.

On top of that, another alternative which also satisfies the second pushback is to reduce your offering to the key solutions that the customer views as vital, which should also reduce the resources you have to expend to provide it and also be able to reduce the price. By seeing that you are willing to negotiate and try to find a solution, you may find that they’re more willing to do business with you. After all, it is a negotiation in many cases and the key to winning negotiations is to create win-win scenarios.

To summarize, the Logical Thinking Processes offer a structured and systematic approach to problem-solving, empowering individuals and organizations to unravel complex issues, identify solutions, and pave the way for effective decision-making. Its emphasis on logic and causality serves as a powerful tool in the continuous improvement and evolution of processes within any organization.

Other TOC Tools

In the Theory of Constraints (TOC), there are other tools that are employed to identify, manage, and improve constraints within a system, depending on the industry they operate in. In every industry, you can use The Five Focusing Steps and The Logical Thinking Processes but the tools below are used for specific industries. Here’s a list of some of the key tools used in TOC which are used for different issues and industries:

- Drum-Buffer-Rope (DBR): A scheduling and production control mechanism designed to maximize throughput by synchronizing the flow of work in a manufacturing environment.

- Buffer Management: This tool is used to manage buffers (time, inventory, etc.) in a manufacturing system to protect the flow through the constraint and improve overall system performance.

- Critical Chain Project Management: A project management technique that considers resource dependencies and aims to prevent multitasking and improve project completion times. This is particularly useful in construction or where you have projects that are different from each other.

- TOC Replenishment: A tool that can be used in Retail businesses to manage inventory and ensure greater customer satisfaction while reducing required investments into inventory.

These tools and methodologies serve as a structured framework to analyze, identify, and manage constraints, thereby optimizing the performance of systems in various industries and organizational settings.

Challenges in Implementing the Theory of Constraints

Implementing the Theory of Constraints (TOC) within an organization can present several challenges, despite its potential to optimize operations and improve overall efficiency. One significant challenge lies in changing the traditional mindset and culture of the organization. TOC often necessitates a shift in thinking, emphasizing a systemic approach to problem-solving, which might clash with established, siloed ways of working. Overcoming resistance to change and ensuring widespread buy-in from all levels of the organization becomes a major hurdle.

Another challenge involves the identification of the actual constraints within the system. Pinpointing the core bottleneck that limits the organization’s performance requires a comprehensive understanding of the entire system. This might demand a significant investment in time, resources, and expertise, as constraints may not always be overtly evident and can exist in unexpected areas. Additionally, external factors or changes in the business environment can cause constraints to shift, requiring constant vigilance and adaptability.

Once identified, addressing the constraints and implementing changes to alleviate them can be challenging. Implementing TOC often involves altering processes, technologies, or even the organizational structure, which might face resistance.

Furthermore, measuring and assessing the success of TOC implementation can be a challenge. It is important that appropriate metrics and KPIs are created and that they align with the strategic and financial goals of the operation.

Conclusion

In conclusion, the Theory of Constraints has emerged as a vital management philosophy that offers a systematic approach to enhancing efficiency and achieving operational excellence. By identifying and managing constraints within an organization, TOC empowers businesses to optimize their operations, reduce waste, and ultimately thrive.